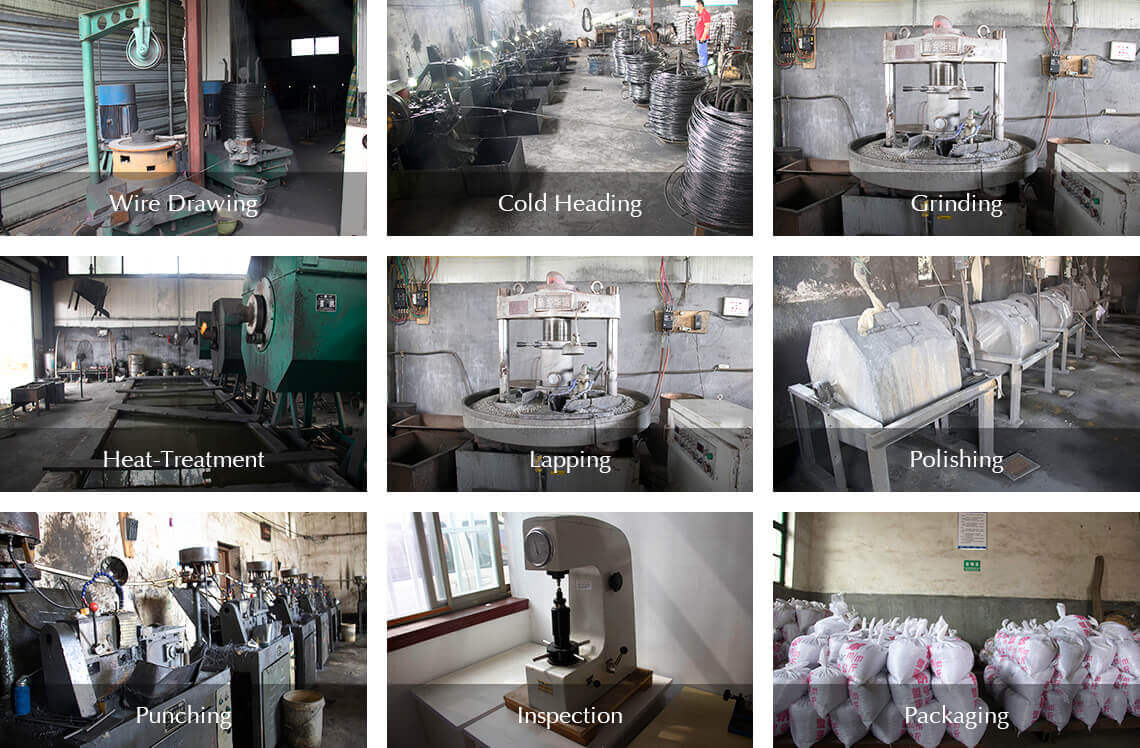

Mingliang manufactures over five billion balls each year in a range of sizes and materials. Most are of stainless steel, carbon steel and chrome steel, while the rest are from aluminum, brass, copper and precious metals. Mingliang has a special department devoted to the manufacture of precious metal balls, including gold, silver, platinum, palladium, titanium and specialized alloys, for uses such as electrical contacts, switches, relays, brazing and jewelry. Each material has unique production requirements, but the process is generally similar and has been refined over decades for efficiency and uniform quality.

All Mingliang processes and policies are designed for maximum quality. Defects are so rare that we measure them in parts per million, and we won't be satisfied until we find none. Every ball passes through exacting inspections that automatically detect and remove off-spec balls. A significant number of random samples is tested for hardness and examined microscopically for structure and finish.

Only when we know that customers will be satisfied do we impart the Mingliang name to our products. Mingliang's high standards for quality and value also apply to the extensive line of metal burnishing media that we manufacture.